Electric vehicle (EV) is a term used to describe a transport vehicle that is solely or jointly propelled by an electric motor, in particular Battery Electric Vehicles(BEV) do not have a combustion engine as found in a typical car on the road. This is replaced by an electric motor or in some cases like a Tesla, multiple motors which drives the cars wheels.

There is generally no gear lever or change needed as acceleration is achieved by a variation in power going to the motor. This is all powered by a high density battery bank usually located under the car in place of the fuel tank.

There is generally no gear lever or change needed as acceleration is achieved by a variation in power going to the motor. This is all powered by a high density battery bank usually located under the car in place of the fuel tank.

Hybrid Vehicles use a combination of both combustion engine and electric motor to optimise fuel efficiency driving. They have a battery pack on board that powers the electric motor. The battery gets charged by an on-board high efficiency charger when the engine is operating and by regenerative braking. Regenerative Braking is a term used to describe a system of putting a charge back into the batteries using the Kinetic energy of the Vehicle when the brakes are applied.

On speeds below around 20-50km the Vehicle runs on electric motor only. When the motorist accelerates, the engine seamlessly kicks in and takes over. On some performance Hybird Vehicles, such as Lexus, to increase the torque (pulling power) the Vehicle can use a combination of the engine and the electric motor for quicker acceleration when required.

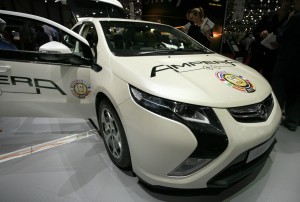

Plug-in Hybrid Electric Vehicles (PHEV) or sometimes called Range Extenders ( Opel Ampera/Volt) are essentially an electric car with a backup engine to re-charge the batteries and power the car when needed. They have a larger battery bank (usually lithium-ion) and use the electric motor as the primary source for powering the car, while using the petrol/Diesel engine as a last resort and kicking in when the batteries loose power. The advantages of a PHEV over a regular Hybrid is that they have a larger range on Electric only driving, you have the comfort of a backup engine should the batteries deplete and the motorist can re-charge the vehicle at home or use a public charge point when needed instead of refueling.

Most Hybrid vehicles primarily use the engine to move the car but will automatically choose between driving on fuel only, electric only or a combination of both depending on the driving conditions, where as most PHEVs use the electric motor to power the car and use the engine to charge the battery and take over when the battery looses power.

Despite their potential benefits, widespread adoption of Battery Electric Vehicles (BEVs) faces several hurdles and limitations. As of 2012 Electric Vehicles are still significantly more expensive than conventional internal combustion engine vehicles and Hybrid Electric Vehicles due to the additional cost of their lithium-ion battery pack. However, battery prices are coming down with mass production and expected to drop further. Other factors that are discouraging the adoption of electric cars is the re-charging infrastructure and the driver’s fear of the batteries running out of energy before reaching their destination (range anxiety). However, this is likely to change, as to date there are 1,200 public charge points in Ireland. ( see www.evcompare.ie/carchargemap)

A gear less or single gear design in EVs eliminates the need for gear shifting, giving such vehicles both smoother acceleration and smoother braking. Because the torque of an electric motor is a function of current, not rotational speed, electric vehicles have a high torque over a larger range of speeds during acceleration, as compared to an internal combustion engine. As there is no delay in developing torque in an EV, EV drivers report generally high satisfaction with acceleration.

A gear less or single gear design in EVs eliminates the need for gear shifting, giving such vehicles both smoother acceleration and smoother braking. Because the torque of an electric motor is a function of current, not rotational speed, electric vehicles have a high torque over a larger range of speeds during acceleration, as compared to an internal combustion engine. As there is no delay in developing torque in an EV, EV drivers report generally high satisfaction with acceleration.

Most of the running cost of a Battery Electric Vehicle can be attributed to the maintenance and replacement of the battery pack because an electric vehicle has only around 5 moving parts in its motor, compared to a Petrol or Diesel car that has hundreds of parts in its internal combustion engine. Electric cars have expensive batteries that must be replaced but otherwise incur very low maintenance costs, particularly in the case of current Lithium based designs.

To calculate the cost per kilometre of an electric vehicle it is therefore necessary to assign a monetary value to the wear incurred on the battery. This can be difficult due to the fact that it will have a slightly lower capacity each time it is charged and is only considered to be at the end of its life when the owner decides its performance is no longer acceptable. Even then an ‘end of life’ battery is not completely worthless as it can be re-purposed, recycled or used as a spare.

Electric motors can provide high power-to-weight ratios, and batteries can be designed to supply the large currents to support these motors. Although some electric vehicles have very small motors, 15 kW (20 hp) or less and therefore have modest acceleration, many electric cars have large motors and brisk acceleration. In addition, the relatively constant torque of an electric motor, even at very low speeds tends to increase the acceleration performance of an electric vehicle relative to that of the same rated “Horsepower” motor power internal combustion engine.